News & Information

The 257-ton “Big Mac” was successfully hoisted !

Jun 3,2021

The 257-ton “Big Mac” was successfully hoisted! At 6:50 on November 10th, the first wind turbine of the State Power Investment Corporation Jiangsu Rudong H4# and H7# offshore wind farm project undertaken by Zhongtian Technology Group Offshore Engineering Co., Ltd. was successfully hoisted, marking the largest single unit capacity in China, Dongfang’s largest offshore wind power proje……

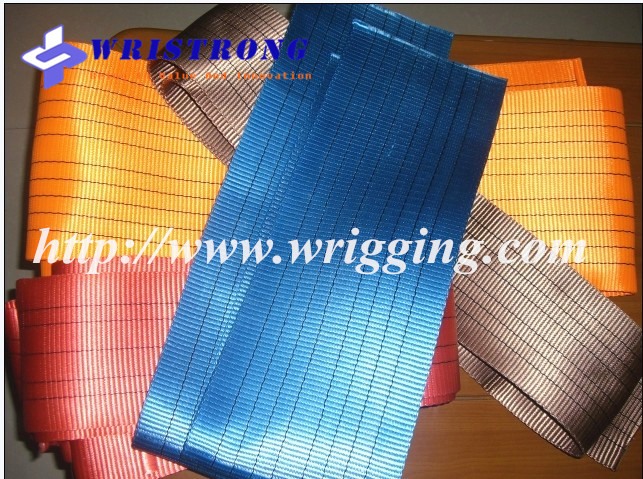

Read MoreWhat are the differences between webbing slings and round slings ?

Jun 3,2021

What are the differences between webbing slings and round slings? Common Lifting slings in the market are divided into endless slings and eye to eye slings, but there are often some misunderstandings in the specific distinction between lifting round slings and flat webbing slings. It is necessary to understand the difference between these two type of lifting slings, in order to buy the right sl……

Read MoreIntroduction on our city-Hangzhou

May 7,2021

Welcome to Hangzhou China Hangzhou formerly romanised as Hangchow, is the capital and largest city of Zhejiang Province in Eastern China. It sits at the head of Hangzhou Bay, which separates Shanghai and Ningbo. Hangzhou grew to prominence as the southern terminus of the Grand Canal and has been one of the most renowned and prosperous cities in China for much of the last millennium, du……

Read MoreFlatbed Lashing Tie-down Systems And Regulations

Apr 8,2021

Flatbed Lashing tie-down systems and regulations Protect your equipment, employees, and the public with best practices for securing cargo. The American Trucking Associations’ Technology and Maintenance Council offers practical guidelines for inspecting and maintaining cargo securement equipment, such as mounting assemblies for winches, which can take a beating with day-to-day use.……

Read MoreWristrong in-house Quality Control on Webbing slings

Apr 8,2021

Regarding to in-house Quality Control on Webbing slings Of China Wristrong Factory is always emphasizing quality control, while it’s totally true but how many factories could make the real quality control into their daily production activities? Our quality control start from materials selection. Take webbing sling as an example: 1.Polyester yarn selection: All of our polyester yarn are f……

Read MoreChina Heavy Lift Round Slings and Webbing Slings

Apr 8,2021

Heavy Lift Round Slings,Webbing Slings from China-Wristrong Industry Wristrong Industry is glad to inform our valued customers that as the new machines imported, we are able to produce the heavy duty round slings W.L.L up to 500Tons(SF:7:1) and heavy duty webbing slings W.L.L up to 40Tons(SF:7:1). Wristrong Industry has been in reserching and producing in heavy duty lifting slings in China (poly……

Read MoreHow to Select and use wire rope slings – Wristrong Industry China

Apr 8,2021

How should you select the proper wire rope sling? Follow the manufacturers’ charts and tables on sling types, angles, and rope diameters and select a proper sling which suits the load and the slinging method that you are going to use. Sling types can be endless, single, two, three or four leg. The sling must be both long enough and strong enough for the load and the slinging method……

Read MoreHow to Choose the Webbing Material for Lifting Slings ?

Apr 8,2021

How to Choose the Webbing Material for Lifting Slings The first step in choosing an appropriate web sling is to determine what material you need the sling to be made of. There are several different lifting slings to choose from including nylon slings, polyester round slings, wire rope slings, and chain slings. By looking at the properties of a lifting sling, it will help you determine what ……

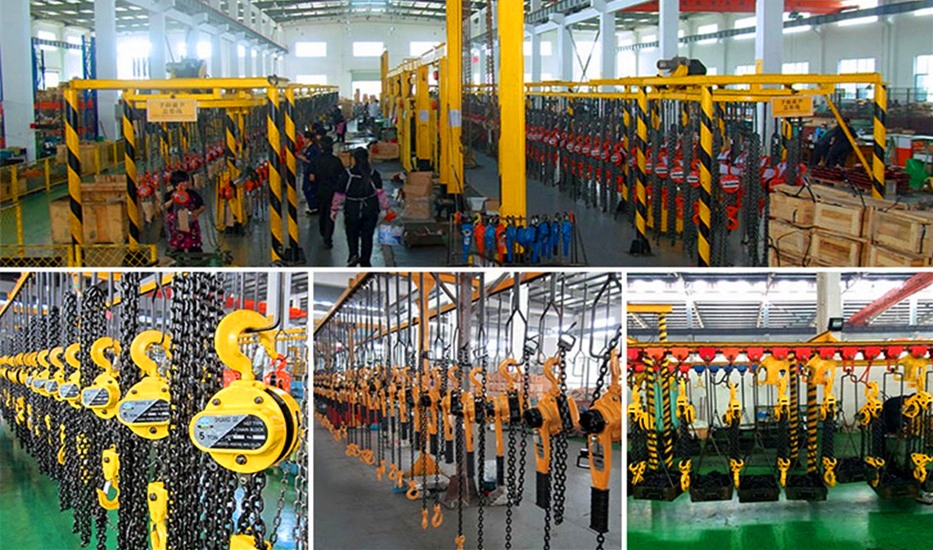

Read MoreHow to Use of Lever Block / Chain Hoists – Wristrong Industry China

Apr 8,2021

When should you inspect the materials hoists? Schedule a detailed inspection of all hoists. Follow the manufacturers’ recommended maintenance schedules. Inspect hooks, ropes, brakes and limit switches for wear and damage every working day. Replace items not operating properly. Tag defective items and remove from service for repair by a competent person. Post the safe load limit on ……

Read MoreHow to use slings onto a crane hook ?

Apr 8,2021

How to use slings onto a crane hook How should you sling a load onto a crane hook? Make clear signals according to standard signals. Refer to “Materials Handling – Crane and Hoist Hand Signals” for examples. Signal the crane operator from only the one slinger who is in charge of lift. The only exception is a stop signal. (A slinger or rigger is the person who hooks loa……

Read MoreThe Safety Guide Of Chain Slings And Lifting Chain

Apr 8,2021

Overhead lifting chain slings are useful tools for various types of overhead lifting operations and are frequently used for material handling in construction and manufacturing. Following industry guidelines is key to optimizing the use of these slings in a safe and effective manner. Why is safety such an important issue for overhead lifting? Lifting or applying loads in any direction is incredi……

Read MoreSome Professional Terms Explanation in Lifting and cargo control Inudstries

Apr 8,2021

Safe working load (SWL) is the load that a lifting device such as a crane, a cherry picker, or a lifting arrangement can safely lift, suspend or lower. Other synonyms include working load limit (WLL), which is the maximum working load designed by the manufacturer. The load represents a mass or force that is much less than that required to make the lifting equipment fail or yield. The SWL is cal……

Read More