Use Instruction-Waist Belt-According to EN358:2000

This device is used for protection again falling; for proper use, see supervisor, or instructions, or

call

Wristrong Industry.Most of safety belts have been approved by Certification body: STP (Secretary of the Safety Technical

Testing Laboratory), Adalbert-Stifter-Straße 65,A-1200 Vienna (Notified Body 0511) and STP

will also be carrying out the ongoing

assessment.

These products are classed as Personal Protective Equipment (PPE) by the European PPE Directive

89/686/EEC and have been shown to comply with this Directive through the Harmonised

European Standard EN 354:2002 Personal protective equipment against falls from a height

:Lanyards

CAREFULLY READ THESE INSTRUCTIONS BEFORE USING THIS PRODUCT

This product is designed to minimize the risk of/provide protection against falling and the dangers

resulting from falling down.

However, always remember that no item of PPE can provide full protection and care

must always be taken while carrying out the risk-relation activity.

Description & Application

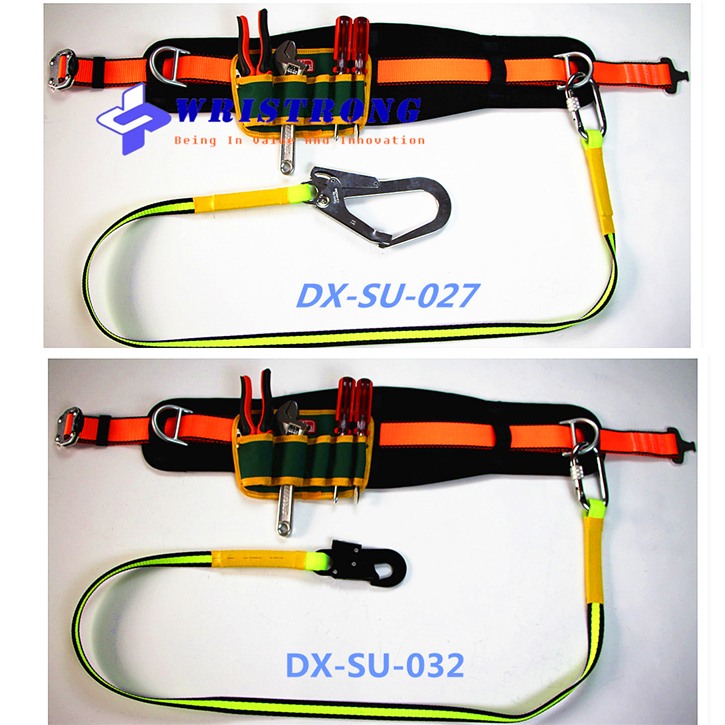

Waist belt with wide contoured comfort pad and a rigid bow "D" ring each side for the attachment

of work positioning devices. Manufactured from polyester webbing with non-corrosive fittings.

Work positioning systems are intended for use by workers required to work at heights on poles or

other structures in a supported position, thereby enabling

Thread free end of webbing up between knurled bar and fix piece of webbing on buckle. Then pass

free end of webbing back down between knurled bar and end of buckle so the European caution

motif/emblem is visible.

Modification and Repairs

No repairs, modifications or alterations are to be carried out on this work positioning belt.

Rescue Plan

As part of your risk assessment, you MUST have in place a rescue plan to deal with any emergency

which may occur during use. Access to the user, directly or indirectly, and their safe retrieval is of

paramount importance, including preparations for dealing with potential Post Fall Suspension

Trauma.

Inspection

The pre-use check must include (but is not limited to):

★ Check all webbing/ rope for signs of cuts, abrasions, fraying tears, burns, mold , discoloration or

chemical attack.

★ Check all stitching for signs of loosening, pulling or cut thread. There must be no evidence of

damaged stitching on either side of the stitch pattern.

★ If the belt has been subject to significant paint overspray, it must not be used.

★ Adjusters and connectors MUST be free from rust, excessive wear, distortions or cracks and

regularly check during the use.

If during the pre-use check any part is found to be or believed to be faulty. DO NOT use it.

Remove ALL components from site to ensure that they cannot be use by anyone.

Users of this equipment should be free from any medical conditions that could affect the safe

usage of the equipment.

Cleaning, Maintenance Storage and Transportation

You may clean the belt of light soiling, using warm water with pure soap or mild detergent. Heavy

deposits of creosote or grease may be removed with a diluted solution of heavy detergent and

water.

Avoid getting soap / detergent into buckles. After cleaning, rinse thoroughly with fresh clean water

then remove excess water with a dry cloth. Finally, allow the belt to dry naturally then give it a

full inspection before storing.

Store in a cool dry place, which will protect the belt from extreme humidity, direct heat and

sunlight. Allocate a storage area specifically for belt. If the belt is wet, allow to dry naturally

before storing. For transportation, it should be packed in a textile bag of them to have both

hands free for working. They are not intended for fall arrest. When working using a work

positioning device, it should normally be used in conjunction with a fall arrest system.